Speedy Systems In [advertising] Revealed

An Introduction To Root Factors In

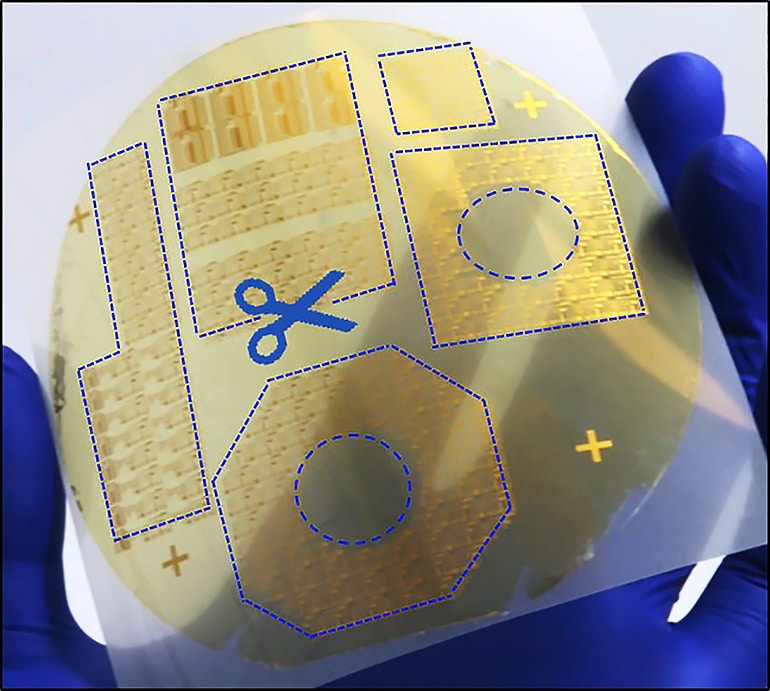

(Credit: Chi Hwan Lee/Purdue) High temperatures and etching damage the silicon wafer, however, forcing the manufacturing process to accommodate an entirely new wafer each time. Lee’s new fabrication technique, called “transfer printing,” cuts down manufacturing costs by using a single wafer to build a nearly infinite number of thin films holding electronic circuits. Instead of high temperatures and chemicals, the film can peel off at room temperature with the energy-saving help of simply water. Gas sensors are like tiny electronic rescue dogs “It’s like the red paint on San Francisco’s Golden Gate Bridge—paint peels because the environment is very wet,” Lee says. “So in our case, submerging the wafer and completed circuit in water significantly reduces the mechanical peeling stress and is environmentally friendly.” A ductile metal layer, such as nickel, inserted between the electronic film and the silicon wafer, makes the peeling possible in water. Researchers can then trim these thin-film electronics and paste them onto any surface, granting that object electronic features. Putting one of the stickers on a flower pot, for example, made that flower pot capable of sensing temperature changes that could affect the plant’s growth. Lee’s lab also demonstrated that the components of electronic integrated circuits work just as well before and after they were made into a thin film peeled from a silicon wafer. The researchers used one film to turn on and off an LED light display. 2D crystals may enable future super-thin electronics “We’ve optimized this process so that we can delaminate electronic films from wafers in a defect-free manner,” Lee says.

(Credit: Chi Hwan Lee/Purdue) High temperatures and etching damage the silicon wafer, however, forcing the manufacturing process to accommodate an entirely new wafer each time. Lee’s new fabrication technique, called “transfer printing,” cuts down manufacturing costs by using a single wafer to build a nearly infinite number of thin films holding electronic circuits. Instead of high temperatures and chemicals, the film can peel off at room temperature with the energy-saving help of simply water. Gas sensors are like tiny electronic rescue dogs “It’s like the red paint on San Francisco’s Golden Gate Bridge—paint peels because the environment is very wet,” Lee says. “So in our case, submerging the wafer and completed circuit in water significantly reduces the mechanical peeling stress and is environmentally friendly.” A ductile metal layer, such as nickel, inserted between the electronic film and the silicon wafer, makes the peeling possible in water. Researchers can then trim these thin-film electronics and paste them onto any surface, granting that object electronic features. Putting one of the stickers on a flower pot, for example, made that flower pot capable of sensing temperature changes that could affect the plant’s growth. Lee’s lab also demonstrated that the components of electronic integrated circuits work just as well before and after they were made into a thin film peeled from a silicon wafer. The researchers used one film to turn on and off an LED light display. 2D crystals may enable future super-thin electronics “We’ve optimized this process so that we can delaminate electronic films from wafers in a defect-free manner,” Lee says.

For the original version including any supplementary images or video, visit https://www.futurity.org/electronic-stickers-internet-of-things-1814192/

พิมพ์สติ๊กเกอร์ราคาถูก สกรีนหลอดครีม ราคา

No comments:

Post a Comment